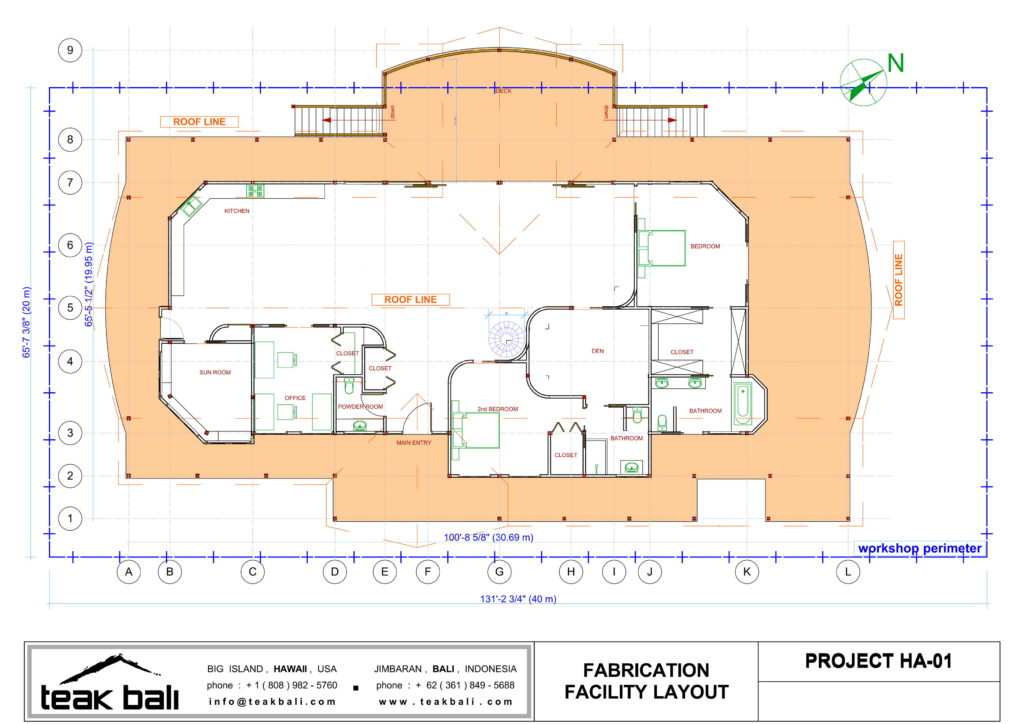

As soon as the Hardwood Garage was knocked down, finished and placed into the loading area of the warehouse, we then had the space to begin production on the Main structure. Due to the large size of this Hardwood Knockdown House, careful planning had to be done in terms of the placement of the structure within our warehouse. Teak Bali had actually never fabricated such a large Wooden Knockdown Home and the curved front Bearer of the front deck needed to stick out from the warehouse into the garden. We needed to intelligently review the dimensions of our production facility (65 feet x 131 feet / 20m x 40m) against the 5,758 ft/535 m2 footprint of this very large Wooden Knockdown House. Because of the amount of raw materials and man hours required, our project manager, quantity surveyor and head carpenter needed to carefully analyze and plot out the entire fabrication process from receipt of raw materials right down to the stuffing of the 6 containers. The biggest concerns were regarding placement of the raw material throughout the fabrication process and the knockdown phase. The Skeleton of the Hardwood Knockdown Home required 75 cubic of Merbau and 27 cubics of Bangkirai (Not including the Flooring/Decking/Siding and Door/Window packages). This oversize structure ended up requiring two 20 footers and four 40 footers in all. So our Project manager carefully plotted the entire project in Microsoft Project so we could balance the time, space and requirements as well as manage the Human Resources.

Because we were dealing with over 100 cubic of raw materials, the prep work on this structure regarding S4S (Sanding 4 Side) as well as the Pre-notching was quite timely. And once the Post and Beam wooden Floor structure began to take shape, most of the ensuing prep work needed to occur underneath the structure itself. Teak Bali’s production facility is quite large compared to most of our peers here in Indonesia but this large Hardwood Knockdown house was still quite a challenge for us. Once the Post and Beam Floor Structure was standing, the work was extremely manageable but during the preliminary stages of fabrication as well as the knockdown/finishing/stuffing stages, this is when Teak Bali’s analytical and systems skills were allowed to shine. If you have a desire to design something with a large footprint, Teak Bali has the skills and abilities to build Wooden Knockdown Homes at any size.

Please keep your eyes out for our next episode on this Hawaii HA-01 project where we write about the receipt of the Garage shipment into the client’s job-site in Hawaii. For prior Blog articles and information on this project, please click here: “Hawaii Project A”.